How actual equipment usage insights helped one company improve lab efficiency

In the age of the biotech boom with technological advances bringing sweeping transformations to the industry, operations management will only continue to grow in importance.

Scientific operations (SciOps) and laboratory operations (LabOps) teams are positioned to have a strategic role in the operational and capital success of companies. They are the lifeblood of biotech and pharma labs. These small, agile teams manage everything from procurement and inventory to asset management and facilities planning.

One way that LabOps teams can communicate their value is by demonstrating improved efficiencies within their purview. This can be accomplished in a variety of ways, but often fall into 3 main categories - costs, people, and time.

Elemental Machines strives to empower LabOps teams to become strategic partners in their organization’s operations. The LabOps Intelligence Platform can help labs take control of operational and scientific data by connecting the physical and digital worlds into a single dashboard or existing systems via an application programming interface (API). With the launch of Elemental Machines’ Usage Solution, labs can now get a handle on equipment utilization, adding a new layer of functionality to the platform.

Improving operational efficiency through reallocation of lab funds

Elemental Machines recently caught up with Arbor Biotechnologies (Arbor Bio) who implemented the Usage Solution into a sampling of their lab equipment.

The Cambridge, MA-based bio-discovery company leverages CRISPR-based genomic editors to develop next-generation genomic medicines. The company has just over 100 employees, operates about 30,000 square feet of lab space, and is rapidly expanding. Arbor Bio currently leases out 7,500 square feet of its facilities, but due to growth, this space will be returned back to Arbor Bio for operations starting in mid-2023.

With the rapid growth, Arbor Bio’s SciOps team – led by Scientific Operations Manager, Aseim Bhaskar – is constantly fielding requests from scientists and other lab members for additional lab space and more resources.

In this case, the team was asking for a new biosafety level 2 (BSL2) area. They claimed that the tissue culture biosafety cabinet (BSC) in the current space was not available when needed, thus slowing experimental progress. Bhaskar estimated the cost of this expansion would be around $200,000.

To evaluate this request, the team implemented the Usage Solution to validate equipment data and justify the cost of the expansion project. The SciOps team also uses a lab scheduling software, to capture user-generated data on equipment reservations. The Solution was specifically used to confirm suspected discrepancies between reservation times and actual usage times.

How the Usage Solution works

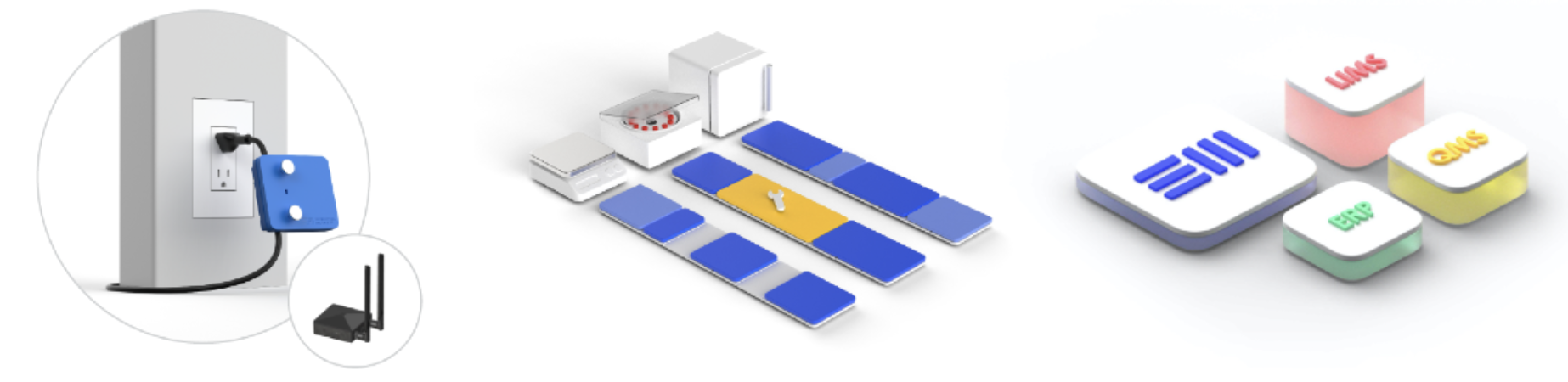

- A battery-operated smart device clamps to a power cord & a gateway machine sends data securely to the Elemental Machines Cloud

- Data science analyzes usage data every minute and visually displays real-time, timeline, and utilization rates to provide teams with actionable insights

- Data can be connected with ease and securely sent to existing QMS, LIMS, ELN, and/or other software platforms

The Solution helped the Arbor Bio SciOps team:

- Take control with a complete picture of the lab with usage data

- Align CapEx and OpEx spending to company growth

- Use real-time data to improve team efficiency

With the implementation of the Usage Solution, the SciOps team was able to measure actual equipment usage that guided data-driven purchasing decisions and improved lab efficiency. Furthermore, Bhaskar assured the team that they had enough BSC capacity to tide them over until the company reclaims the additional 7,500 square feet of space next year. Ultimately, the lab was able to spend funds in more essential areas thereby lessening the burden on existing equipment.

“The $200,000 would have been spent anyway since it was in the lab’s operating budget," Bhaskar said. "So, at least we ended up using that money to buy high-throughput instruments instead of having another BSL2 space.”

To learn more about how Arbor Bio went about implementing the Usage Solution and the results they saw:

Never miss a beat...

Subscribe to our bi-monthly EM Connect Newsletter to stay up-to-date on all things LabOps, biotech, and more!